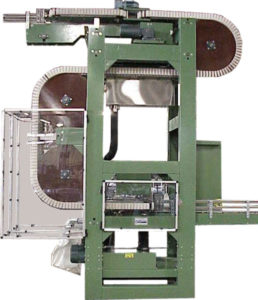

Lowerator rinsers are used for irregular and non-round containers. Side grip lowerator rinsers use the same frame and specifications as the standard side grip elevators/lowerators.

Containers from an overhead conveyor to the filler infeed are lowered and inverted with 180º turns in the gripper chain conveyor. Meter belts at the infeed of the lowerator can be used to space containers for adequate rinsing.

- Water rinsers have a lengthened frame to drain water after rinsing before re-inverting the container.

- Ionized air rinsers re-invert the container immediately after rinsing with 180º turns in the gripper chain conveyor.

Water Rinsers utilize water spray nozzles which are attached to a common manifold to direct water to the inside of the container.

Ionized Air Rinsers utilize a series of air nozzles which spray ionized air into the container to neutralize static electricity that may be holding any foreign debris to the inside of the container. A second set of air nozzles spray filtered air into the container to blow out any foreign debris. A remote vacuum system removes debris from the rinser hood and is collected into a canister.