The Zone Touch™ case conveyor system is designed to handle cases safely without the use of rollers.

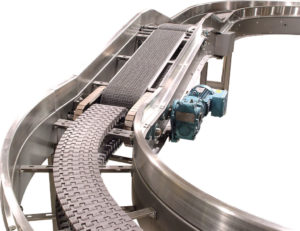

This system offers more up-time than conventional roller and fabric belt systems by using table top chain throughout the system. Zone Touch also offers a conveyor system that has a noise level far less than conventional roller conveyor systems by using a table top chain that rides in UHMW wear strips and return ways. Zone Touch is designed for handling larger cases than other table top chain conveyor systems, without adjustment, by using a 6” wide chain throughout the 16” BB frame series. Curve sections are equipped with 6” wide flex mat top chain with hold down tabs. Inclines/declines are designed with 6” wide rubberized plastic chain, powered feeders and nose over levelers. Smaller product can be handled with the 12” BB frame series that utilizes 4” table top chain, and has the same accessories.

The primary feature of the Zone Touch case conveyor system are the accumulators. The accumulators are self-contained with individual electrical and pneumatic controls. Zone Touch utilizes a short stroke air cylinder with a non-binding, low maintenance lift linkage providing ultra-quick positive response and increased durability over the “air bag” method found in most systems. Each intermediate section has all controls, wiring and air tubing in a protective housing attached to the conveyor frame. A simple connection at the end of each intermediate bed section connects the control wiring and pneumatic system for each accumulator section.